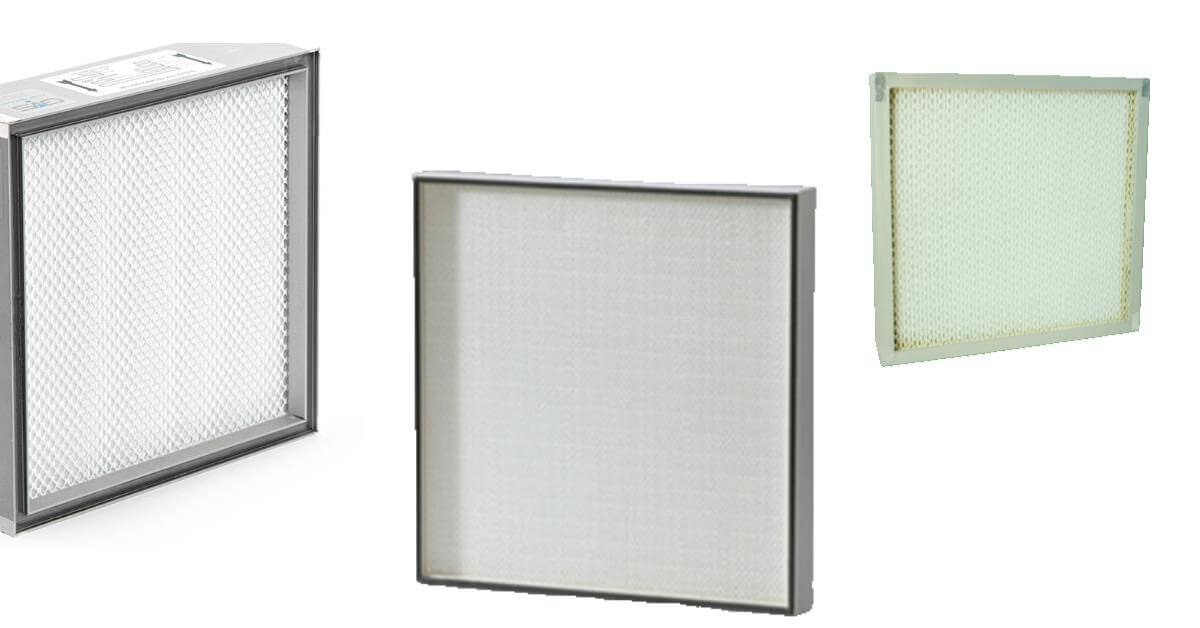

Mini Pleat HEPA Filters are revolutionizing the way industries maintain clean and safe air environments. Designed with cutting-edge technology, these filters utilize a micro-pleated design to maximize surface area while maintaining compactness. This innovative approach not only enhances efficiency but also ensures superior air quality, making Mini Pleat HEPA Filters the preferred choice for critical applications like cleanrooms, operating theaters, and laboratories.

What sets these filters apart is their ability to achieve high filtration efficiency—up to 99.999%—while maintaining a low-pressure drop. This translates to better energy efficiency and reduced operational costs over time. Industries such as pharmaceuticals, biotechnology, and food processing rely heavily on these filters for their ability to handle stringent air cleanliness requirements. The lightweight and durable design also ensures ease of installation and handling, making them a practical choice for both new and retrofitted systems.

Additionally, the versatility of Mini Pleat HEPA Filters allows them to be customized for various dimensions and efficiency levels, ensuring they meet specific industry standards. Whether it’s their robust construction with aluminum or galvanized steel frames or the inclusion of silicone gaskets for leak-proof operation, these filters deliver exceptional performance. Their widespread adoption underscores their significance in maintaining hygiene and safety across multiple sectors.

What Are Mini Pleat HEPA Filters?

Think of Mini Pleat HEPA Filters as an advanced version of regular HEPA filters. They combine precision engineering with cutting-edge technology to deliver exceptional air filtration.

Key Components of Mini Pleat HEPA Filters

- Filter Media: Made of microfine glass fiber, ensuring high filtration efficiency.

- Frame Material: Constructed from durable materials like aluminum, galvanized steel, or stainless steel, depending on application needs.

- Pleating Technology: Mini pleats are spaced with hot melt adhesive beads for maximum airflow and minimal pressure drop.

These components work together to make Mini Pleat HEPA Filters incredibly efficient and long-lasting.

Features and Benefits of Mini Pleat HEPA Filters

Why are minipleat hepa filters gaining so much attention? It’s all about the features and benefits they bring to the table.

1. Exceptional Efficiency

Mini pleats increase the filter surface area, allowing for higher particle capture rates. These filters achieve efficiency levels from 99.99% to 99.999%, ensuring even microscopic particles like bacteria and viruses are filtered out.

2. Lower Pressure Drop

Compared to conventional deep pleat HEPA filters, Mini Pleat HEPA Filters have a significantly lower pressure drop. This means your ventilation system works more efficiently, reducing energy costs over time.

3. Lightweight and Compact Design

The thin and lightweight design of these filters makes them easy to handle and install, especially in compact spaces.

4. Customizable Options

Available in a variety of sizes and materials, these filters can be tailored to specific requirements. Whether it’s gasket seals for leak-proof operation or unique dimensions, customization is a breeze.

Technical Specifications of MiniPleat HEPA Filters

Understanding the technical side gives us a clearer picture of their capabilities.

| Specification | Details |

|---|---|

| Efficiency Range | From E10 to U15 |

| Filter Media | Microfine glass fiber |

| Frame Material | Aluminum, galvanized steel, or aluminum with gel seals |

| Depths Available | 30mm to 150mm |

| Accessories | Gaskets, grilles |

This versatility ensures that Mini Pleat HEPA Filters are suited for a wide range of applications.

The Science Behind Mini Pleat HEPA Filters

How do they achieve such high filtration efficiency? Let’s break it down:

1. Microfine Glass Fiber Media

The primary filter media consists of waterproof, pleated glass fiber. This material is highly effective at trapping particles as small as 0.3 microns.

2. Hot Melt Adhesive Technology

Hot melt adhesive beads are used to create uniformly spaced pleats. This design optimizes airflow while minimizing resistance, ensuring consistent performance.

3. Thermoplastic Resin Separators

These separators enhance the filter pack’s density without compromising airflow, allowing for more particles to be captured.

Companies That Offer Mini Pleat HEPA Filters and Their Costs in USD

When considering Mini Pleat HEPA Filters, it’s essential to know which companies provide the best options and what they charge. Several renowned manufacturers offer high-quality filters tailored to various needs. Below are some leading companies and approximate price ranges for their filters in the U.S. market:

1. GVS Filtration

- Overview: GVS is a trusted name in air filtration, offering Mini Pleat HEPA Filters with micro-pleated designs for optimal performance and long service life.

- Pricing: $50 – $150 per unit (depending on size and efficiency level).

2. Camfil

- Overview: Camfil specializes in providing high-efficiency filters for cleanrooms, pharmaceuticals, and healthcare facilities. Their filters are known for reliability and durability.

- Pricing: $80 – $300 per unit (customizable options may cost more).

3. AAF International

- Overview: AAF International provides a variety of filters, including Mini Pleat HEPA Filters, with low-pressure drop designs that ensure energy efficiency.

- Pricing: $60 – $200 per unit (pricing varies with specifications).

4. HVDS (High-Velocity Duct Systems)

- Overview: HVDS manufactures and supplies filters designed for critical environments, ensuring compliance with industry standards.

- Pricing: $75 – $250 per unit.

5. Koch Filter Corporation

- Overview: Koch Filter Corporation offers a wide range of filters, including custom-sized Mini Pleat HEPA Filters, suitable for cleanrooms and industrial applications.

- Pricing: $70 – $180 per unit.

6. Flanders Corporation

- Overview: Known for their expertise in clean air solutions, Flanders Corporation provides Mini Pleat HEPA Filters designed to meet strict cleanliness standards.

- Pricing: $100 – $250 per unit.

Factors Influencing the Cost of Mini Pleat HEPA Filters:

- Filter Grade: Higher grades (H13, H14) cost more due to increased efficiency.

- Custom Specifications: Tailor-made sizes or materials like stainless steel frames may add to the price.

- Quantity: Bulk purchases often come with discounts.

- Application Needs: Filters for critical environments like cleanrooms might cost more.

When choosing a supplier, it’s essential to evaluate your specific requirements and compare options. Investing in a high-quality Mini Pleat HEPA Filter ensures better performance and long-term savings.

Applications of Mini Pleat HEPA Filters

These filters are designed for critical environments where clean air is non-negotiable. Here are some common use cases:

1. Healthcare and Medical Facilities

- Operating Theaters: Maintain a sterile environment by filtering out airborne contaminants.

- Clean Rooms: Ensure ISO Class 5 cleanliness for sensitive procedures.

2. Pharmaceuticals and Biotechnology

Used in laminar flow hoods and production lines to prevent contamination of products.

3. Research Laboratories

Protect sensitive experiments by maintaining particle-free air.

4. Food and Beverage Industry

Ensure hygienic conditions during food preparation and packaging.

Pro Tip: Mini Pleat HEPA Filters are factory-tested and scanned to meet stringent performance standards, ensuring reliability in critical applications.

Comparing Mini Pleat HEPA Filters to Traditional HEPA Filters

Let’s see how Mini Pleat HEPA Filters stack up against their traditional counterparts.

| Feature | Mini Pleat HEPA Filters | Traditional HEPA Filters |

|---|---|---|

| Efficiency | Up to 99.999% | Up to 99.97% |

| Pressure Drop | Lower | Higher |

| Design | Compact and lightweight | Bulky and heavier |

| Cost-Effectiveness | More economical over filter lifespan | Higher operational costs |

The advantages are clear—Mini Pleat HEPA Filters outperform in almost every category.

FAQ on Mini Pleat HEPA Filters

What is a mini pleat HEPA filter?

A mini pleat HEPA filter is a high-efficiency air filter designed with densely packed, micro-pleated layers of filter media. This design increases the surface area for filtration while maintaining a compact form factor, ensuring optimal particle capture and airflow.

Are HEPA filters pleated?

Yes, HEPA filters are pleated to maximize the surface area of the filter media. This pleating enhances filtration efficiency by allowing the filter to trap more particles while maintaining proper airflow.

What is mini pleat?

Mini pleat refers to a specific design technique where the pleats in the filter media are more tightly packed than conventional pleats. This configuration increases filtration efficiency, reduces pressure drop, and saves space.

What are the three classes of HEPA filters?

HEPA filters are classified based on their efficiency:

H10 to H12: High-efficiency filters (85%–99.5% filtration efficiency).

H13 to H14: True HEPA filters (99.95%–99.995% efficiency).

U15 to U17: ULPA (Ultra-Low Penetration Air) filters for the highest filtration efficiency (>99.999%).

DheerajSonwane is a dedicated writer with expertise in air purification technologies. He focuses on providing well-researched content to help readers improve indoor air quality in homes and businesses. As the lead writer at AirPurifierMaster.com, Dheeraj offers practical advice his insightful reviews guide individuals in choosing the best air purifiers for their needs.