The Electrostatic Precipitator Troubleshooting Guide with Q&A serves as a comprehensive resource to help identify, understand, and resolve common issues in ESP systems. Electrostatic precipitators are vital for reducing particulate emissions and maintaining compliance with environmental regulations, but like any complex system, they can experience challenges. This guide is designed to simplify troubleshooting by providing practical answers to frequently asked questions, ensuring your ESP operates efficiently and effectively.

When troubleshooting an ESP, it’s crucial to understand the interplay between various components like collecting plates, discharge electrodes, rapping systems, and hoppers. Each of these elements plays a pivotal role in maintaining the system’s performance. Common issues such as sparking, higher emissions, or back corona can stem from misalignments, improper settings, or external factors like ash properties and flue gas characteristics. By addressing these root causes, you can ensure smoother operations and reduced downtime.

Moreover, this guide takes a practical Q&A approach, making it easy to pinpoint problems and implement solutions quickly. Whether you’re dealing with support insulator failures, field voltage drops, or fluctuating ESP currents, the answers provided here are tailored to help you troubleshoot with confidence. With the right knowledge, maintaining the performance and longevity of your ESP becomes a straightforward task.

What Is an Electrostatic Precipitator and How Does It Work?

To troubleshoot something effectively, you need to understand how it works. So, let’s first unravel the science behind electrostatic precipitators (ESPs).

The Basics of ESP Technology

An electrostatic precipitator is an air pollution control device that uses an electric field to remove particulate matter, like dust and smoke, from flue gas. Here’s how it works:

- Charging Particles: Dirty air enters the ESP, where particles are given an electric charge by passing through a corona discharge field.

- Collection Plates: The charged particles are attracted to oppositely charged collection plates, where they stick.

- Particle Removal: Periodic rapping or cleaning removes the collected particles, sending them to hoppers for disposal.

The process is elegant yet prone to complications, which is why a solid troubleshooting guide is essential.

Common Issues in Electrostatic Precipitators

Even the best systems can run into hiccups. Let’s discuss some of the most frequent challenges you might face when operating an ESP.

1. Decreased Efficiency

If your ESP isn’t capturing as much particulate matter as it should, it could be due to:

- Improper Voltage Levels: Low voltage might fail to adequately charge particles.

- Dirty Collection Plates: Accumulated debris can reduce the plate’s ability to attract particles.

What to Do:

- Check and adjust the power supply to maintain the correct voltage.

- Regularly clean the plates to prevent buildup.

2. Spark Overload

Too many sparks can disrupt the ESP’s operation and damage components. Sparks usually occur due to:

- Excessive Dust Loading: If too much particulate matter enters the ESP, it increases the risk of sparking.

- Misaligned Electrodes: Uneven spacing can cause voltage instability.

Solution:

- Reduce the dust load by pre-filtration if necessary.

- Inspect and realign electrodes to maintain even spacing.

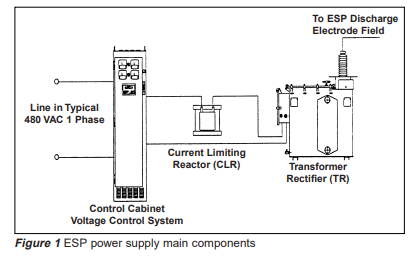

3. Electrical Faults

Electrical issues can bring an ESP to a standstill. Common causes include:

- Short Circuits: Caused by damaged wiring or grounding issues.

- Power Supply Problems: Faulty transformers or rectifiers can disrupt operations.

Fix It Fast:

- Inspect wiring and insulation regularly.

- Test power components and replace any faulty parts.

Step-by-Step Troubleshooting Guide for Your ESP

Here’s a detailed electrostatic precipitator troubleshooting guide to help you pinpoint and resolve problems effectively.

Step 1: Monitor System Performance

Start by evaluating your ESP’s overall performance. Look for signs of reduced efficiency, excessive emissions, or abnormal sounds.

- Check the Control Panel: Ensure all readings, like voltage and current, are within the recommended range.

- Visual Inspection: Look for visible damage, leaks, or excessive dust accumulation.

Step 2: Inspect Key Components

Break down your inspection into the following areas:

A. Electrodes and Plates

- Look for signs of warping, misalignment, or wear on electrodes.

- Ensure collection plates are clean and free of excessive buildup.

B. Power Supply

- Test transformers and rectifiers to ensure consistent voltage.

- Check grounding to avoid short circuits.

C. Insulators

- Examine insulators for cracks or contamination. Dirty insulators can cause electrical faults.

Step 3: Address Environmental Factors

Sometimes, the problem isn’t the ESP itself but external conditions. For example:

- High Humidity: Moist air can interfere with corona discharge.

- Dust Characteristics: Sticky or high-resistivity dust may require adjustments to the ESP settings.

Step 4: Test After Repairs

After making adjustments or repairs, monitor the system closely to ensure the issue is resolved. Check emission levels and ensure all components are functioning correctly.

Maintenance Tips for a Trouble-Free ESP

Prevention is always better than cure. Regular maintenance can significantly reduce the chances of problems cropping up.

1. Daily Monitoring

- Keep an eye on voltage, current, and emissions to detect issues early.

- Clean collection plates and electrodes regularly.

2. Periodic Inspections

- Schedule detailed inspections of key components every few months.

- Replace worn-out parts promptly to avoid cascading failures.

3. Optimize Dust Handling

- Ensure hoppers are emptied regularly to prevent backflow into the system.

- Adjust operating parameters to match the type of dust being handled.

4. Invest in Training

Properly trained operators are your first line of defense against ESP problems. Regular workshops and training sessions can go a long way in improving system performance.

Benefits of Using an Electrostatic Precipitator Troubleshooting Guide

Why is this electrostatic precipitator troubleshooting guide worth your time? Let’s take a moment to appreciate the benefits.

- Improved Efficiency: By diagnosing and fixing issues quickly, you ensure your ESP captures the maximum amount of particulate matter.

- Cost Savings: Avoid expensive repairs and downtime by catching problems early.

- Environmental Compliance: A well-maintained ESP helps you meet strict air quality regulations.

By following this guide, you’re not just maintaining a machine—you’re contributing to cleaner air and a healthier planet.

When to Call an Expert

While this troubleshooting guide is comprehensive, some situations require professional intervention. Here are a few scenarios where expert help might be necessary:

- Persistent electrical faults despite repairs.

- Difficulty diagnosing complex issues, like airflow disruptions.

- Major structural damage to the ESP.

Don’t hesitate to seek expert advice to keep your ESP running smoothly.

Some other pdf resource you can refer:

“https://unicous.com/wp-content/uploads/2021/08/esp-tsg.pdf”

“https://www.nwl.com/wp-content/uploads/pdf/esp-troubleshooting-guide.pdf”

Electrostatic Precipitator Troubleshooting Q&A Guide

1. What are the potential reasons for large dust collection on collecting plates and discharge electrodes?

- Higher dust load on ESP: Excessive particulate matter entering the ESP leads to increased dust collection.

- Improper rapping: Inefficient or infrequent rapping prevents proper cleaning of the collecting plates.

- Low velocity of flue gas: A slow-moving flue gas stream allows particles to settle excessively on the plates.

- Higher resistivity of ash: High resistivity ash does not conduct the charge well, causing particles to stick to the plates.

- ESP running under capacity: When the ESP operates below its design capacity, it can accumulate more dust due to uneven flow distribution.

2. Why is there sparking in the ESP fields

- Excessive dust formation on plates: Thick layers of dust create uneven charge distribution, leading to sparking.

- Very small gap between collecting plates and emitting electrodes: Inadequate spacing causes voltage breakdowns.

- Improper alignment of electrodes: Misaligned electrodes disrupt the electrical field and increase the chance of sparks.

- Obstacle of foreign material: Foreign objects touching discharge electrodes can cause sparking.

- Improper charge ratio: Incorrect voltage-to-current ratios can destabilize the electric field, leading to sparking.

3. What are the reasons for higher emissions at the stack outlet?

- Improper charging of particles: If particles are not adequately charged, they bypass the collection plates and exit with the flue gas.

- Overloaded ESP: When the ESP is handling more particulate matter than its design allows, some particles escape.

- Dirty collecting plates or electrodes: Layers of dust reduce the efficiency of particle collection.

- Back corona effect: High resistivity ash causes ionized gases to neutralize the charge, reducing collection efficiency.

- Faulty rapping system: Poor cleaning of plates can lead to re-entrainment of particles into the gas stream.

4. What causes damage or corrosion of ESP electrodes and casing plates?

- Operation at lower flue gas temperatures (<120°C): Cold flue gases cause condensation, leading to corrosion.

- Excessive ash deposition: Heavy layers of ash increase stress on plates and electrodes.

- Air leakages in the ESP: Ingress of cold air causes condensation and corrosion.

- Inadequate insulation: Poor insulation materials fail to maintain optimal temperature levels, promoting condensation.

- Improper rapping system operation: Excessive or insufficient rapping damages electrodes and plates.

- Ash not cleaned during shutdowns: Residual ash during shutdowns accelerates corrosion.

5. Why is there a difference in hopper temperatures of ESP fields?

Hopper temperatures vary due to the different ash loads handled by each ESP field.

- Higher ash discharge: Fields collecting more ash have higher hopper temperatures due to heat transfer from hot ash.

- Lower ash discharge: Fields with less ash show lower hopper temperatures.

6. What is the Back Corona effect?

The Back Corona effect occurs when:

- High resistivity dust layers ionize the gas near the collecting plates.

- Positive ions flow back toward the discharge electrodes, neutralizing the negative ion current.

- This phenomenon reduces the system’s voltage and collection efficiency.

Solution: Increase the rapping frequency to remove high-resistivity ash layers.

7. Why is there fluctuation in ESP current and voltage?

Fluctuations in current and voltage can occur due to:

- Sparking events: Frequent sparking disrupts electrical stability.

- Uneven dust loading: Irregular particle flow causes inconsistent resistance.

- Misaligned electrodes: Misalignments cause voltage imbalances.

- Back Corona: High resistivity ash layers cause inconsistent ionization.

8. Why do support insulators fail?

Support insulators fail due to:

- Higher operating temperatures: Extreme heat can crack or degrade the material.

- High dust collection and electrical arcing: Accumulated dust increases the risk of electrical faults.

- Shock loads: Mechanical shocks or vibrations damage the insulators.

Prevention:

- Ensure proper cooling mechanisms.

- Regularly clean insulators to avoid dust accumulation.

- Minimize vibrations during operation.

9. Why is more ash collected at the first ESP field compared to others?

- In the first field, the flue gas velocity drops significantly, from around 12 m/s to 1 m/s, allowing a large proportion of ash to settle.

- As a result, the current for the first field is kept lower than for subsequent fields to prevent overloading.

10. Why does ESP field voltage reduce when the current increases?

This occurs due to the Back Corona effect caused by high-resistivity ash. The ionized gas near the collecting plates creates positive ion backflow, reducing voltage levels.

Solution: Increase the rapping frequency to prevent ash accumulation.

11. Why do explosions occur in ESPs, and how can you avoid them?

Explosions in ESPs are typically caused by:

- Combustible gases: Presence of flammable substances like carbon monoxide or hydrocarbons.

- Sparks: High-energy sparks ignite flammable gas mixtures.

- Insufficient purging: Improper startup or shutdown procedures leave flammable gases in the ESP.

Prevention:

- Ensure proper purging of gases before startup or shutdown.

- Maintain clean and dry electrodes.

- Avoid operation under conditions that allow combustible gas accumulation.

12. Additional Q&A: Common ESP Issues

Q: Why is my ESP rapping system ineffective?

- Possible Causes:

- Worn-out rapping hammers or anvils.

- Improper rapping frequency settings.

- Weak mechanical linkages.

- Solution: Inspect and replace faulty components regularly. Adjust rapping frequency based on the dust type.

Q: Why is ash re-entrainment happening in my ESP?

- Possible Causes:

- Excessive airflow velocity.

- Faulty hopper sealing causing ash to re-enter the gas stream.

- Solution: Reduce airflow velocity and ensure hoppers are properly sealed.

Q: What causes ESP hopper blockages?

- Possible Causes:

- Ash bridging due to moisture.

- Low hopper temperatures causing condensation.

- Solution: Use heating elements to maintain hopper temperatures and prevent ash bridging.

Conclusion: Mastering ESP Troubleshooting for Optimal Performance

Electrostatic precipitators are robust and effective devices, but like any system, they require regular maintenance and prompt troubleshooting to function optimally. By understanding the potential causes of common issues, like sparking, high emissions, or insulator failures, you can keep your ESP in peak condition.

This guide empowers you with actionable steps to address challenges, improve efficiency, and prevent costly downtimes. Remember, consistent monitoring and maintenance are the keys to ensuring your ESP operates smoothly and meets environmental compliance standards.

Maintaining an electrostatic precipitator doesn’t have to be overwhelming. By understanding how your ESP works, recognizing common problems, and following this electrostatic precipitator troubleshooting guide, you can ensure optimal performance and longevity for your system.

Remember, a proactive approach to maintenance saves time, money, and stress in the long run. So, keep this guide handy, and tackle ESP issues with confidence!

If you enjoyed this discussion and found it helpful, feel free to explore more resources on industrial equipment troubleshooting and maintenance right here on our platform.

DheerajSonwane is a dedicated writer with expertise in air purification technologies. He focuses on providing well-researched content to help readers improve indoor air quality in homes and businesses. As the lead writer at AirPurifierMaster.com, Dheeraj offers practical advice his insightful reviews guide individuals in choosing the best air purifiers for their needs.