AHU (Air Handling Unit) and pre filter for AHU are essential components that help remove dust, pollen, and other particles from the air before it circulates through the building. In simple terms, the pre filter is the “first line of defense,” capturing larger particles to protect the finer filters in the system. It’s a smart solution to improve air quality and protect the AHU’s more sensitive components. But how does it actually work, and why is it so crucial for air systems?

Pre Filter for AHUs are designed to catch the bigger particles floating in the air, such as dust, fibers, and even pollen. Think of them as the “gatekeepers” that make the air cleaner for everyone inside, whether it’s a bustling office, a school, or a hospital. By trapping these larger contaminants, the pre filter reduces strain on the system’s main filters, allowing them to focus on the finer particles. This setup not only makes the AHU more efficient but also helps extend the lifespan of the filters, saving time and money on replacements.

For anyone managing or maintaining an AHU, understanding the role of pre filters is essential. From knowing how often they need replacing to the types available, a little knowledge goes a long way in keeping your AHU running smoothly. Whether you’re a building manager, a technician, or just curious about air quality, learning about Pre Filter for AHUs can give you a clearer picture of how these systems keep indoor air fresh and healthy. Let’s dive into the details of why these filters matter and how they make a difference in maintaining clean air.

Introduction to Pre Filter for AHU

Air Handling Units (AHUs) play a huge role in maintaining indoor air quality, especially in commercial and industrial spaces. But here’s something you might not know – one of the unsung heroes in this system is the pre filter. These filters are responsible for catching larger particles before the air reaches the AHU’s finer filtration stages.

In this article, we’ll dive into what makes pre filters for AHU so important, the types available, specifications, and much more. Think of it as your ultimate guide to understanding and choosing the right pre filter to keep your air cleaner and your AHU running smoothly.

Why Pre Filters are Crucial in Air Handling Units

So, what’s the big deal with pre filters? Think of them as the first line of defense in your AHU. They’re like the gatekeepers, trapping larger particles like dust, dirt, and hair before they can make their way further into the system. This not only helps improve air quality but also protects the AHU components from getting clogged or damaged.

Protecting AHU Components

Without a pre filter, all sorts of debris would end up clogging fans, coils, and other AHU components, leading to more wear and tear. A clogged system has to work harder to move air, and that extra strain can cause breakdowns or the need for costly repairs.

By catching these larger particles, pre filters allow the AHU’s more sensitive filters – like fine or HEPA filters – to last longer and work more effectively. This results in less frequent filter replacements, fewer repairs, and a longer lifespan for the entire system.

Enhancing Indoor Air Quality (IAQ)

When you install a pre filter for AHU, you’re making an investment in indoor air quality (IAQ). The cleaner the air going through the AHU, the less dust and particulate matter ends up in your breathing space. Especially in spaces where people spend a lot of time – offices, schools, hospitals – this can make a noticeable difference in comfort and health.

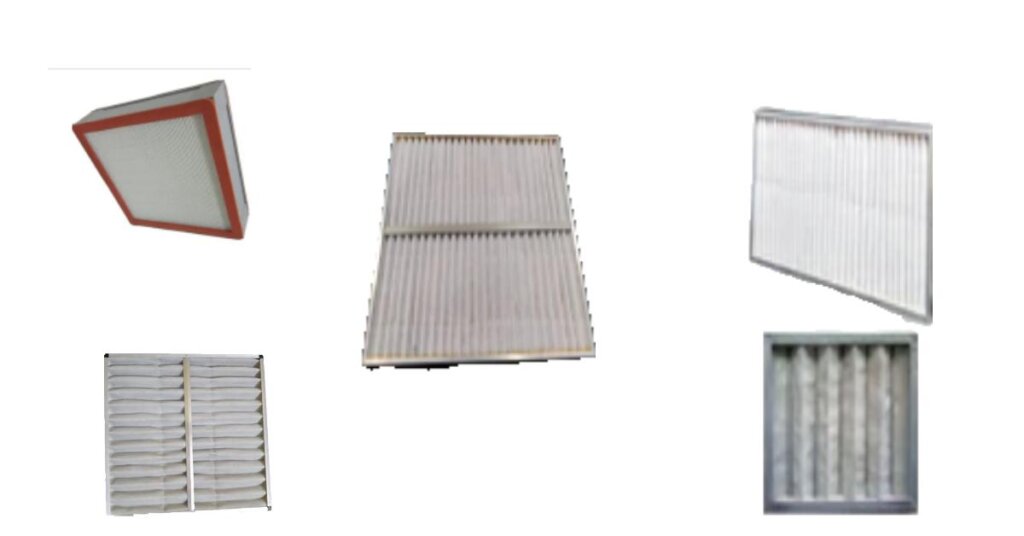

Types of Pre Filter for AHU

Not all pre filters are created equal, and different types suit different needs. Let’s take a look at some popular options.

Panel Filters

Panel filters are the most basic type of pre filter, often used as the first stage of filtration in an AHU. They’re flat, affordable, and usually come in fiberglass or polyester. These filters are great at catching larger particles but may not capture smaller dust or allergens, making them ideal as a primary filter in areas without extreme air quality demands.

Pleated Filters

Pleated filters add an extra layer of filtration by using a pleated design, which increases the surface area. This means they can capture more dirt and fine particles than panel filters. Pleated filters are often used in areas where moderate air filtration is required, and they tend to last longer than basic panel filters due to their design.

Washable vs. Disposable Filters

There’s also the choice between washable and disposable filters. Washable filters are more durable and environmentally friendly since you can clean and reuse them, while disposable filters are single-use and need replacement after they’re clogged. Each option has its pros and cons, so choosing one depends on your AHU’s needs and maintenance capabilities.

Pre Filter for AHU Micron Size

The micron size of a filter is a big deal because it tells you the size of particles that the filter can capture. A “micron” is one-millionth of a meter – super small! For AHU pre filters, typical micron sizes range from 5 to 50 microns, where smaller micron ratings capture finer particles.

Why Micron Size Matters

Filters with a smaller micron size capture finer particles but can also increase airflow resistance. This means that while they clean the air more thoroughly, they may require more frequent maintenance or replacement to keep air moving smoothly. Choosing the right micron size depends on the level of air quality you want and the specific environment where the AHU is used.

Pre Filter for AHU Price

When it comes to purchasing a pre filter for AHU, price is often a key consideration. Prices for AHU pre filters can vary based on a few factors like type, brand, and materials used. Typically, simple panel filters cost less than pleated or high-efficiency filters.

Factors Affecting Pre Filter Price

- Material Quality: Basic fiberglass panel filters are the most affordable, while pleated filters or those with specialty materials can cost more.

- Filter Size: Larger filters or custom sizes for specific AHU setups can drive up costs.

- Reusable vs. Disposable: Washable filters have a higher upfront cost but may be cheaper in the long run as you can clean and reuse them multiple times.

Buying filters in bulk can also help save costs, especially for facilities that use multiple AHUs. It’s helpful to calculate how often you’ll need replacements and factor that into your overall maintenance budget.

AHU Pre Filter Types

As mentioned earlier, AHU pre filters come in several types, each suited to different environments and filtration needs. Here’s a quick guide to some common AHU pre filter types.

Synthetic Panel Filters

Synthetic panel filters use materials like polyester or polypropylene, making them lightweight and effective for basic air filtration. They’re often used as the first line of defense in AHUs, particularly in commercial spaces where air quality needs are moderate.

Metal Mesh Filters

Metal mesh filters, typically made of aluminum or stainless steel, are more durable than synthetic filters. They’re also washable, making them a great choice for facilities with high dust levels. While they don’t capture the smallest particles, they’re excellent for heavy-duty environments.

Pleated Synthetic Filters

Pleated synthetic filters have more surface area due to their pleated design, allowing them to capture finer particles than basic panel filters. These are ideal for environments with higher air quality demands or where airborne contaminants need to be reduced.

AHU Pre Filter Specifications

Understanding AHU pre filter specifications is important when choosing the right filter for your needs. These specifications help you gauge how well a filter will perform and whether it’s compatible with your AHU system.

Efficiency Rating

Each filter type has an efficiency rating that indicates how well it captures particles of different sizes. AHU pre filters are generally lower efficiency than fine filters but effective at trapping larger particles.

Airflow Resistance (Pressure Drop)

Airflow resistance, often called pressure drop, is a key specification for AHU filters. Lower pressure drop is ideal because it means the filter allows air to pass through more easily. However, higher-efficiency filters with smaller micron sizes may have a higher pressure drop, which means the AHU will need to work harder.

Filter Thickness and Size

Filter thickness and dimensions are crucial for ensuring that a filter fits correctly in the AHU unit. Common thicknesses include 1, 2, and 4 inches, but custom sizes may also be available. The right filter should fit snugly within the AHU housing without leaving gaps for unfiltered air to bypass.

Fine Filter in AHU

While pre filters handle larger particles, fine filters are designed to capture much smaller particles, such as dust, pollen, and even certain bacteria. Fine filters come after pre filters in the AHU filtration process, providing a second layer of defense.

Importance of Fine Filters

Fine filters are essential in settings where air quality is critical, like hospitals, laboratories, or offices where air contaminants can affect health and productivity. They’re also beneficial in reducing allergens in environments that require high indoor air quality.

Common Types of Fine Filters

- HEPA Filters: Capture 99.97% of particles as small as 0.3 microns. Often used in sensitive environments like medical facilities.

- MERV-rated Filters: MERV (Minimum Efficiency Reporting Value) ratings help to classify filters based on efficiency. Higher MERV ratings indicate finer filtration, suitable for spaces where air quality is a priority.

AHU Filter Specification

Filters in AHUs have multiple specifications that determine their performance and compatibility with your HVAC system. AHU filter specifications can vary widely, so it’s essential to match them with your specific needs.

Efficiency and MERV Rating

Most AHU filters have a MERV rating, which ranges from 1 to 16 for standard filters, while HEPA filters have an even higher efficiency. This rating helps determine how effectively the filter captures particles and is crucial when you need high air quality.

Filter Life and Replacement Interval

Each filter has a recommended replacement interval based on the type, materials, and environment. Pre filters typically require replacement every 1-3 months, while fine filters can last longer, depending on the air quality demands.

Construction Material

AHU filters can be made of different materials like synthetic fibers, glass fibers, or metal mesh. Each material has unique properties that affect durability, filtration capacity, and cost. For example, metal filters are sturdy and reusable, while glass fiber filters capture smaller particles.

Maintenance Tips for AHU Pre Filters

Regular maintenance of AHU pre filters can significantly improve the performance and lifespan of your air handling system. Neglecting filter maintenance can lead to increased energy costs, reduced efficiency, and even system breakdowns.

Regular Cleaning and Replacement

For washable filters, regular cleaning is essential to keep them functioning efficiently. Disposable filters, on the other hand, should be replaced according to the manufacturer’s recommended schedule or whenever they appear dirty.

Monitor Airflow and Pressure

An increase in pressure drop across the filter may indicate that it’s clogged and needs replacement. Monitoring pressure levels helps keep your AHU operating smoothly without unnecessary strain.

Keep a Maintenance Log

Tracking maintenance activities helps you stay on top of filter replacements and cleanings. It’s a simple way to ensure that filters are consistently maintained, prolonging both their life and the overall efficiency of the AHU.

Choosing the Right AHU Pre Filter

Choosing the right pre filter for AHU requires a balance of efficiency, compatibility, and cost. The filter should align with the air quality needs of the environment while being compatible with your specific AHU model.

Determine Air Quality Requirements

Different settings demand different air quality levels. For example:

- Medical Facilities: These need high-filtration filters like HEPA or MERV-rated filters with high efficiency.

- Commercial Spaces: Moderately efficient filters may be enough, especially if the air is recirculated frequently.

Consider Long-Term Costs

Investing in high-quality filters may seem costly upfront but can reduce long-term expenses by lowering maintenance needs and extending the lifespan of the AHU. Reusable filters, although pricier, often offer more value in the long run by cutting replacement costs.

Impact of AHU Pre Filters on Air Quality

Pre Filter for AHU are instrumental in maintaining indoor air quality (IAQ) by filtering out larger airborne particles. Good IAQ contributes to health, comfort, and productivity, especially in commercial or industrial settings.

Reducing Allergens and Pollutants

Effective pre filters reduce allergens like pollen, dust mites, and pet dander, creating a cleaner indoor environment. In public spaces, this can also lower the risk of airborne illnesses.

Improving System Efficiency

With a well-maintained Pre Filter for AHU can work more efficiently. By trapping large particles, pre filters protect fine filters from getting clogged, which reduces strain on the system, optimizes energy consumption, and improves longevity.

AHU Pre Filter Micron Size

Micron size is a key factor in understanding how effectively a filter captures particles. The lower the micron size, the finer the particles the filter can capture.

Typical Micron Size for AHU Pre Filters

Most Pre Filter for AHU are designed to capture particles between 5 and 10 microns. This includes larger particles like dust, pollen, and mold spores.

Micron Size vs. Filter Efficiency

While smaller micron filters capture finer particles, they can also create a higher pressure drop. For this reason, pre filters with larger micron sizes are used to protect finer filters in multi-stage AHU systems.

Installation Tips for AHU Pre Filters

Installing AHU pre filters correctly ensures they function optimally and extend the life of the system. Here are some tips for a smooth installation process.

Fit Filters Securely

Make sure each filter fits tightly within its housing to avoid air bypass. Gaps between the filter and housing can reduce filtration efficiency by allowing unfiltered air to pass through.

Follow Manufacturer Guidelines

Each AHU model might have different specifications, so it’s essential to follow the manufacturer’s guidelines for installing filters. This can prevent installation errors that might impact filter performance.

Regular Monitoring and Filter Replacement Schedule

Maintaining a consistent replacement schedule for pre filters in AHUs is crucial for efficiency and air quality. A set replacement cycle helps prevent unexpected clogs and keeps your system running smoothly.

Track Filter Lifespan

Knowing the lifespan of your filter type—whether 1 month or 3 months—helps keep replacements on time. Some systems even have indicator lights or sensors to alert you when it’s time to replace the filter.

Adapt Schedule Based on Environment

In areas with high levels of pollutants, you might need to replace filters more frequently. Conversely, in cleaner environments, filters may last a bit longer before they become clogged.

Fine Filter in AHU

Fine filters are a step up from pre filters, capturing smaller particles that pre filters may miss. These filters often follow pre filters in a multi-stage filtration system within AHUs.

Efficiency and Applications

Fine filters are often HEPA or MERV-rated filters designed to capture tiny particles, typically as small as 0.3 microns. They’re essential in sensitive areas, including hospitals and labs, where high air quality is critical.

Positioning in the Filtration Process

In most AHU setups, fine filters are placed downstream of pre filters. This positioning helps protect the fine filter from larger particles, extending its service life and maintaining airflow efficiency.

Conclusion

Choosing and maintaining the right pre filter for AHU is essential for efficient operation, reduced maintenance costs, and improved air quality. A well-chosen pre filter protects your AHU from dust and debris, ensuring it runs smoothly and lasts longer. Regular maintenance, monitoring, and adhering to specifications keep your system optimized for performance and air quality.

FAQ on pre filter in AHU

What is the use of pre filter in AHU?

The pre filter in an AHU (Air Handling Unit) captures large dust particles and pollutants before they reach the finer filters, helping to protect the system and improve indoor air quality.

What is the pre filter in HVAC?

In HVAC (Heating, Ventilation, and Air Conditioning) systems, the pre filter is the initial filter that removes larger particles from the air, making the system more efficient and prolonging the life of other filters.

What is the function of pre filter?

The main function of a pre filter is to trap large particles like dust, hair, and pollen, which helps reduce the load on the main filters and improves the system’s overall efficiency.

Is pre-filter required?

Yes, pre-filters are essential in many systems as they protect the main filters, reduce maintenance needs, and help maintain better air quality.

What is the process of pre-filter?

The pre-filtering process involves capturing larger contaminants in the initial stage of filtration, preventing them from clogging the main filters and allowing the air to be more effectively cleaned in the next stages.

DheerajSonwane is a dedicated writer with expertise in air purification technologies. He focuses on providing well-researched content to help readers improve indoor air quality in homes and businesses. As the lead writer at AirPurifierMaster.com, Dheeraj offers practical advice his insightful reviews guide individuals in choosing the best air purifiers for their needs.